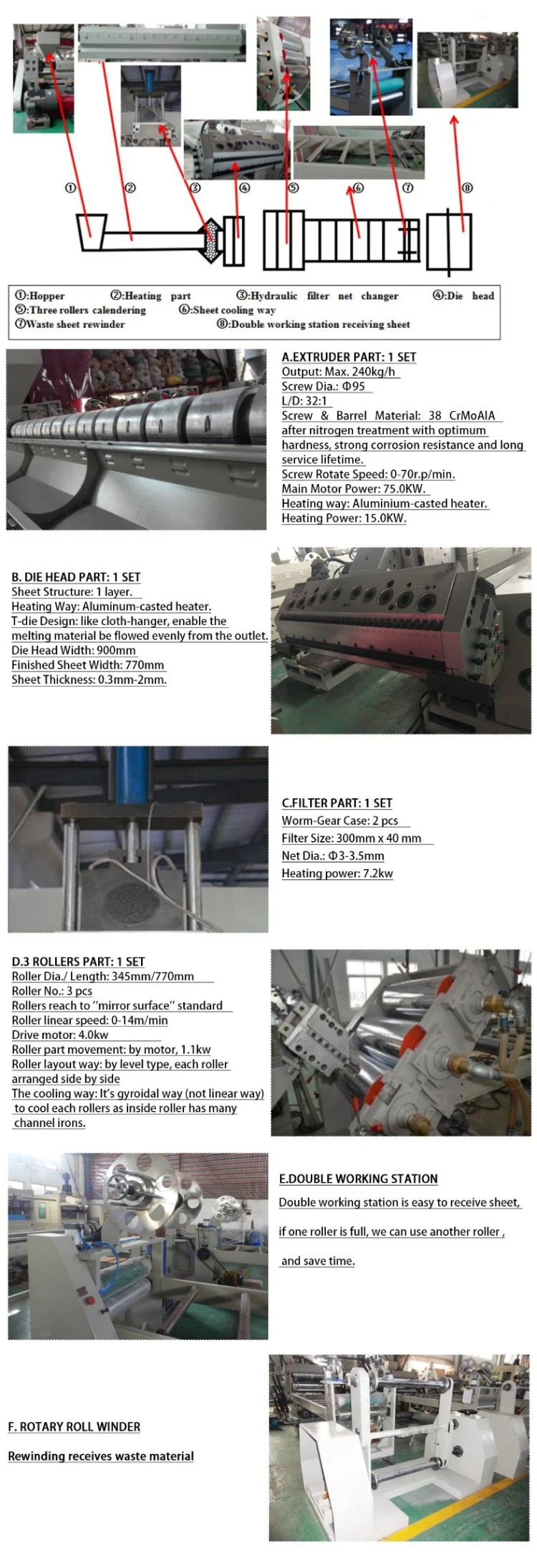

Modle | TJS-670 |

suitable sheet | PP, PS |

Max.sheet width | 670mm |

sheet thickness | 0.3-2.0mm |

Screw rod Dia.(Main machine) | 110 mm |

Screw rod Dia(auxiliary machine) | 80mm |

Screw L/D ratio(main machine) | 30:1 |

Screw L/D ratio(auxiliary machine) | 35:1 |

Main Motor Power | 45kw |

Auxiliary Motor Power | 30kw |

Max. output | 180kg/hr |

Dimension | 11500x2800x2000mm |

Actual Power | 185kw |

weight | 6.6T |

APPLICATION AREA

The sheet extruder is composed of extrusion, calendaring, traction and rolling. The main parts are abrasion resistant, resistant to corrosion, high-temperature resistant by high quality specially-treated. Low resistance force in die head extruding channel makes sheet thickness evenly, the internal spiral tank in three rollers ensures an effective cooling and it is easy to change and install net changer with the hydraulic pressure unit, no need to stop machine. The machine extrudes PP/PS granule to PP/PS sheet with two layers, which is used for producing plastic products by plastic thermoforming machines, like cups, food container, trays, dishes, bowls, lids, etc.

Q1: Are you a factory or trading company?

A1: We are a factory, and we export our machines to more than 80 countries since 2001.

Q2: How long is the warranty period?

A2: We have a professional QC department in charge of products' quality.

Q3: How long is the warranty period?

A3: 13months calculated from the date of shipment from our factory.During warranty period, except the artificial factor, the spares are free to maintenance, beyond the warranty time, the buyer needs to pay the spare charge and shipping cost.

Q4: How to install the machine?

A4: We will send technician to your factory to install the machine, and teach your workers to use it. You pay all related costs, including visa charge, double-way tickets, hotel, meals, and technician salary.