HPMC

Hydroxy Propyl Methyl Cellulose

CAS: 9004-65-3

Formula: C12H20O10

| Other Names | HPMC (2R,3R,4S,5R,6S)-3,4,5-trimethoxy-2-(methoxymethyl)-6-[(2R,3R,4S,5R,6R)-4,5,6-trimethoxy-2-(methoxymethyl)tetrahydropyran-3-yl]oxy-tetrahydropyran 1-[[(2R,3R,4S,5R,6S)-3,4,5-tris(2-hydroxypropoxy)-6-[(2R,3R,4S,5R,6R)-4,5,6-tris(2-hydroxypropoxy)-2-(2-hydroxypropoxymethyl)tetrahydropyran-3-yl]oxy-tetrahydropyran-2-yl]methoxy]propan-2-ol Hydroxypropyl methylcellulose Hydroxypropyl methyl cellulose HPMCP-HP55 |

| CAS | 9004-65-3 |

| Chemical Formula | C12H20O10 |

| Molecular Weight | 324.285 |

| inchi | InChI=1/C36H70O19.C20H38O11/c1-19(37)9-45-17-27-29(47-11-21(3)39)31(48-12-22(4)40)34(51-15-25(7)43)36(54-27)55-30-28(18-46-10-20(2)38)53-35(52-16-26(8)44)33(50-14-24(6)42)32(30)49-13-23(5)41;1-21-9-11-13(23-3)15(24-4)18(27-7)20(30-11)31-14-12(10-22-2)29-19(28-8)17(26-6)16(14)25-5/h19-44H,9-18H2,1-8H3;11-20H,9-10H2,1-8H3/t19?,20?,21?,22?,23?,24?,25?,26?,27-,28-,29-,30-,31+,32+,33-,34-,35-,36+;11-,12-,13-,14-,15+,16+,17-,18-,19-,20+/m11/s1 |

| Melting point | 1.39 |

| Boiling Point | 1101.5°C at 760 mmHg |

| Flash Point | 619.9°C |

| Water Solubility | SOLUBLE |

| Vapor Pressure | 0mmHg at 25°C |

| Physical Property | density 1.39 water SOLUBLE |

| application | dispersant, suspending agent, emulsifier, suspension stabilizer, stabilizer, film former, water retaining agent |

| Safety Terminology | S24/25 - Avoid contact with skin and eyes |

| Materials | 1,2-epoxypropane, methanol, caustic soda, absorbent cotton, hydrochloric acid, chloromethane |

Properties:

HPMC is an important variety of nonionic cellulose mixed ether. It is odorless, tasteless and non-toxic.The finished product is of white powder or loose fiber or granularity through 80 Mesh Sieve. It doesn't react with heavy metals. In the finished product the methoxy content and the hydroxypropyl content proportion is different.And the viscosity is different,it becomes the performance in different variety. HPMC is actually a Methyl cellulose modified by epoxy methane (MMP) , so it has the similar properties of being soluble in cold water , and is more soluble in organic solvents than in water. It is soluble in anhydrous methanol and ethanol, as well as chlorinated hydrocarbons such as dichloromethane, Trichloroethane, and organic solvents such as acetone, isopropanol and diacetone alcohol.

Manufacturing Method:

This product is a semi-synthetic 2-hydroxypropyl ether Methyl cellulose It can be made by two methods: (1) treating cotton fiber or wood pulp fiber with caustic soda, and then successively reacting with chloromethane and 1,2-epoxypropane, which is refined and crushed; (2) treating with suitable grade Methyl cellulose and sodium hydroxide, and reacting with 1,2-epoxypropane under high temperature and pressure to an ideal degree, thus being refined. The molecular weight range is 10000 something 1500000.

HPMC can be prepared in batch mode and continuous mode. Intermittent type is after the cellulose alkalization treatment, after pressing, crushing, mature, in the autoclave and etherifying agent etherifying reaction to make crude products. The continuous type does not need to be pressed, crushed and matured. After alkalization, it is convenient for etherification reaction in high-pressure pipeline reactor and continuous feeding and discharging. The preparation of HPMC mostly uses the liquid phase method, because the uniformity of products made by this method is good. Generally, 35% ~ 50% lye is used to prepare alkali cellulose, and the mass ratio of cellulose to lye is 1:0.5 ~ 2.6.

Property:

This product is white or similar white fibrous or granular powder; odorless .This product is almost insoluble in anhydrous ethanol, ether or acetone.

It swells into a clear or slightly cloudy colloidal solution in cold water.

Discrimination:

1. Take this product 1 G, heated Water (80 °C 90 °C 100 ML) , stirred to form a slurry, cooled in ice bath, to form a viscous liquid; in a 2 Ml test tube, a 0.035% anthrone sulfuric acid solution lm was slowly added along the Tube Wall and left for 5 minutes, showing a blue-green ring at the interface between the two liquids.

2. Identification (1) under the amount of viscous liquid, pour on the glass plate, as soon as the water evaporation, forming a layer of tough film.

3. To retrieve this product. 5 G, evenly dispersed in 50 ML boiling water, electromagnetic stirring to form insoluble slurry, electromagnetic stirring to cool the slurry to 1 CTC to form a clear or slightly turbid solution, adding 50 ml water, electromagnetic stirring and heating simultaneously, at a rate of 2 × 5X: Per Minute, the flocculating temperature to produce turbidity should not be lower than 50 °C.

Viscosity:

·If the marked viscosity is less than 600 MPA · S, the viscosity shall be 80% something 120% of the marked viscosity according to method 1 and 75% something 140% of the marked viscosity according to method 2 if the marked viscosity is greater than or equal to 600 MPA · S.

·Take the proper amount of this product (calculated according to the dried product) , aDD 90X: water to make 2.0% C G / G solution, stir thoroughly for about 10 minutes, until the particles are evenly dispersed and moistened and there are no undissolved sample particles on the inner wall of the bottle. Cool in an ice bath, continue stirring during cooling to remove air bubbles, adjust the weight with cold water if necessary, and remove all the foam as the sample solution.

·Method 1: At 20 T 0. L C, according to the outflow time not less than 200 seconds, using the appropriate inner diameter of UBBELOHDE viscometer to determine the solution of the kinematic viscosity (V, and under the same conditions to determine the density of solution (p)

·Method 2: At 20 T 0. R C, select suitable single-column rotational viscometer Brookfield type LV model or equivalent viscometer according to the following table conditions to determine the general rule 0633 third method) , rotate for 2 minutes, stop for 2 minutes, then repeat the experiment twice, take the average of the three experiments.

Ph:

Add 1.0 g of the product to 50 ML of water at 90 ml while stirring, put it in cold, add water to make the solution 100 ml, stir until the solution is completely dissolved, determine according to law (general rule 0631, Ph value should be 5-8)

Water insoluble Matter:

Take this product from water insoluble matter 1.0 G, in a Beaker, heat the water (80-90X-)100ML swelling about 15 minutes, then cool in the ice bath, add 300ml of water with high viscosity of the sample can appropriately increase the volume of water, to ensure that the solution is filtered) , and fully stir, with 105 °C drying to the constant weight of 1 vertical melting glass crucible filter, beaker with water wash, wash the liquid and the above vertical melting glass crucible, filter, drying at 105C to the constant weight, residue should not be more than 5mg(0.5%) .

Drying Weight Loss:

Take this product, drying at 105 °C for 2 hours, weight loss shall not be less than 5.0% general rule 0831.

SCORCH residue:

Take 1.0 g of this product, check according to law (general rule 0841), residue should not exceed 1.5% .

Heavy Metals:

Take the residue left under the burning residue and check according to law (general rule 0821, second law) , containing no more than 20 parts per million of heavy metals.

Arsenical salt:

Take this product 1.0 g, add calcium dihydroxide 1.0 g, mix, add water to stir evenly, after drying, first with a small fire burning to carbonize, then in 600 c burning to completely ash, put cold, add hydrochloric acid 5ml and water 23tnl to dissolve, according to the first law of the general rule 0822) , should comply with the regulation 0.0002% .

HPMC-content determination:

Methyl chloride is used for this product Methoxy, ethoxy, hydroxypropyloxy method (general rule 0712) . If the second method (volumetric method) is used and the product is accurately weighed, the methoxy content (% minus the product of the hydroxypropyloxy content (% times 31 / 75x093) is determined according to the law.

Hydroxypropyl chloro take this product, according to methoxy, ethoxy, hydroxypropyloxy method (general rule 0712 test if the use of the second method (volumetric method) , take this product 0. 1 G, precision weighing, according to the law, that is, get.

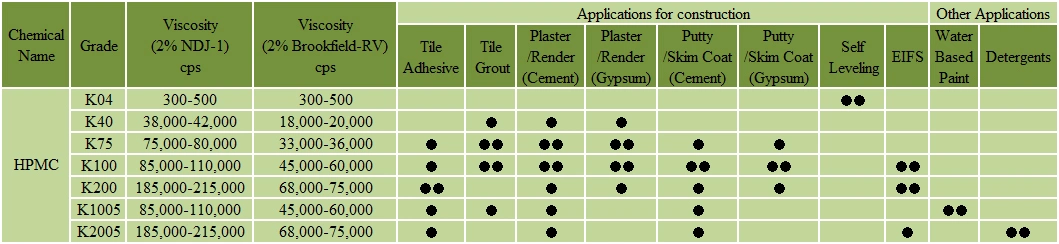

Application:

Q: Are you a trading company or a manufacturer?

A: Manufacturers, welcome to our factory

Q: How long is your lead time?

A: Usually 1-2 weeks, depending on the order quantity

Q: Are the samples free?

A: Accept free sample test, buyer bear delivery charge

Q: What are your payment terms?

A: Payment ≤1000USD, 100% in advance.

Payment terms: > 1000USD, T/T (30% in advance) or l/c at sight

Q: What is your delivery time?

A:Production will be arranged after receiving the deposit, and shipment will be arranged after all payments are made. The delivery time is about 10-15 days.

Certificates:

Company Info: